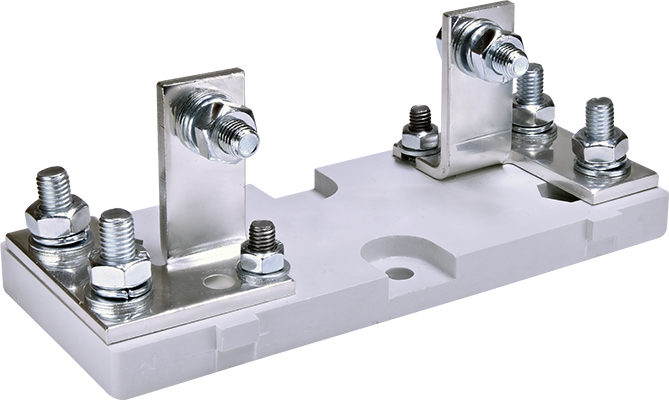

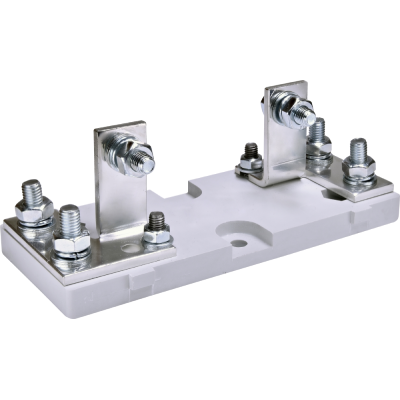

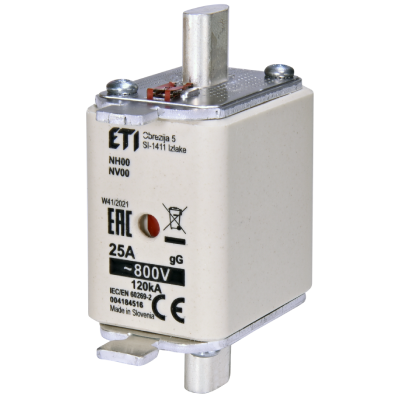

New Drilling and Machining Center for NH Fuse Bodies

As industry pioneers, we lead NH fuse manufacturing for battery storage, photovoltaic systems, and railway applications. Our commitment to quality is evident in the use of superior materials and innovative construction. We manufacture pressed and extruded bodies for low voltage fuses that meet all customers’ technical requirements. Any specific technical demand could be integrated at the body as well. Components are manufactured in accordance with highly demanding process requests that guarantee the best quality to the customer.

| Janik Pikelj |

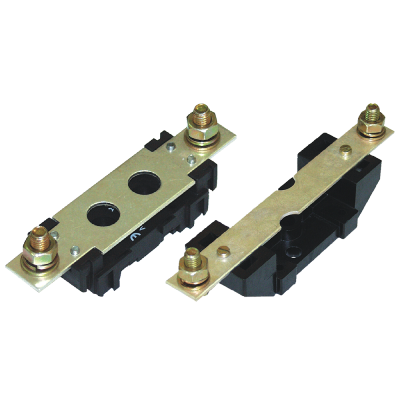

Crafting Technical Ceramics

The production of technical ceramics requires unparalleled precision. From the initial stages of extrusion to the precise refinement after firing, each step requires meticulous attention to detail. Within this process, the production of specialized ceramic NV bases appears as the pinnacle of complexity, requiring a series of complex processing steps.

The Journey of NV Base Drilling Center

The origin of the NV Base center stems from our commitment to go beyond traditional manufacturing methodologies. Challenges such as manual transfers between processing stages, concerns about dust contamination and the need to maintain consistent accuracy have driven our development team to pioneer innovative solutions.

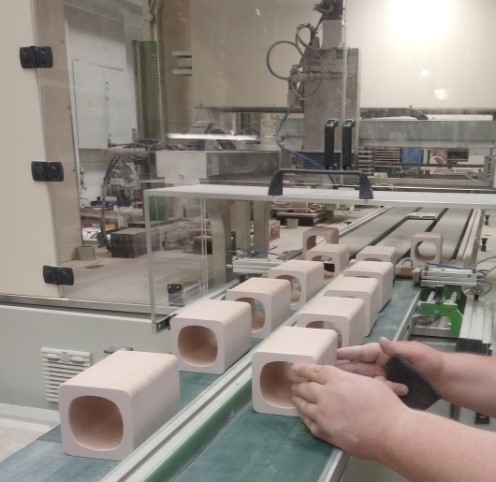

The introduction of the NV Base Drilling and Machining Center heralds a transformative era in ceramic production. By replacing outdated equipment, this state-of-the-art center not only speeds up production processes, but also introduces greater flexibility, reducing labor-intensive tasks. In addition to the direct benefits, the inclusion of advanced technology significantly raises the standards of safety at work, reduces exposure to dust and ensures the well-being of employees.

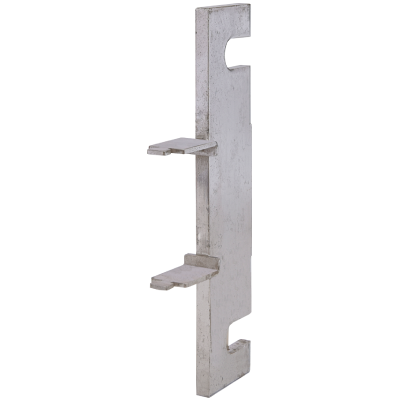

Inserting pieces into the drilling center

Accuracy and Versatility

Characteristic feature of the drilling and machining center is its modular composition, affording the flexibility to service individual units while maintaining uninterrupted operations. Furthermore, the center's capacity to simultaneously produce diverse types of NV bases exemplifies its exceptional versatility, augmenting productivity and resource optimization. The successful integration of the drilling and machining center was made possible through the application of advanced, precision-driven mechanisms and the development of an innovative generation of drills. These sophisticated drills exhibit drilling speeds approximately five times faster and a durability that surpasses conventional counterparts by three to fourfold. This leap in performance is attributed to cutting-edge designs, efficient dust expulsion mechanisms, smooth drive systems, and elevated rotational speeds facilitated by the drilling and machining center.

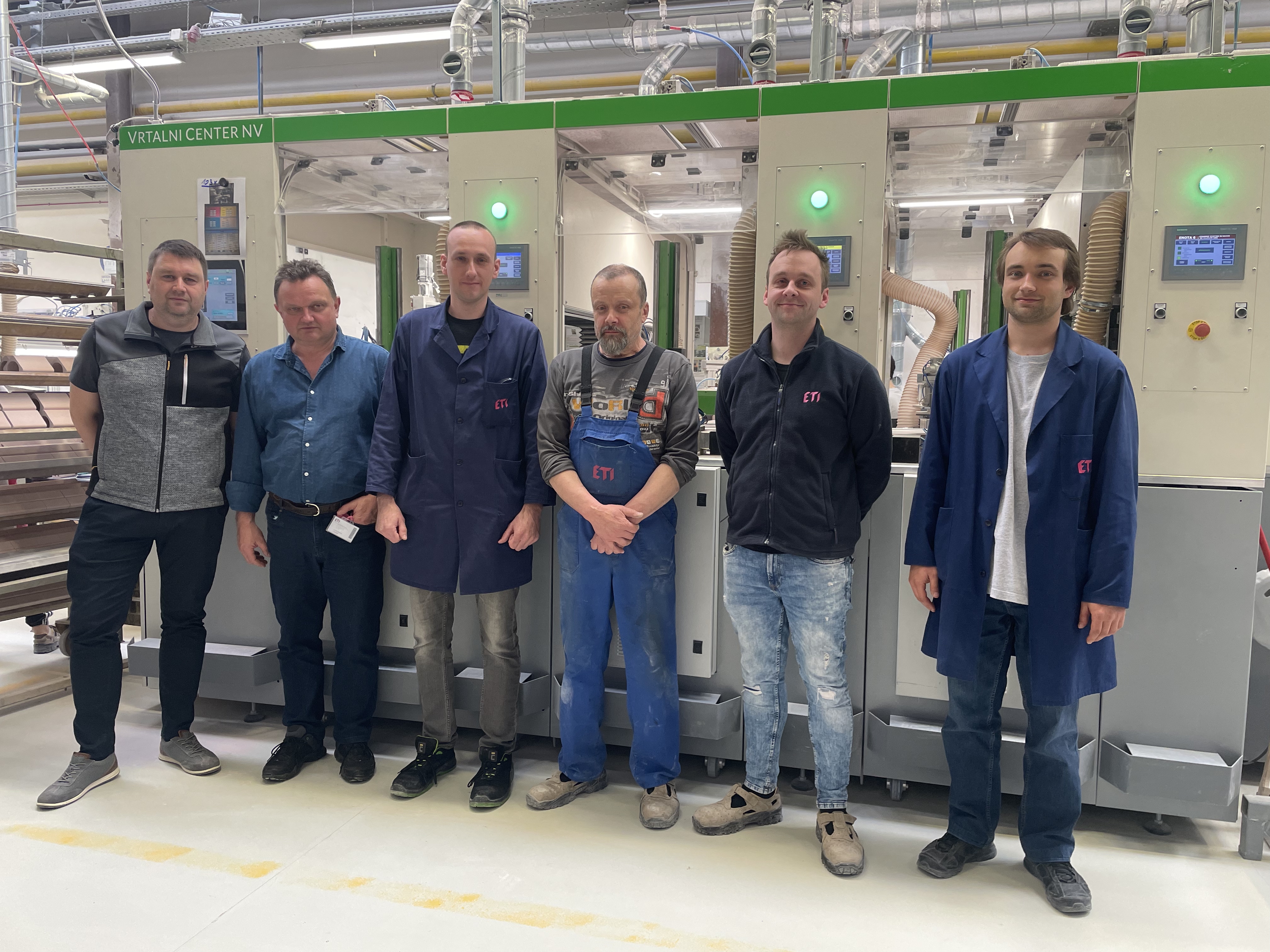

The realization of the NV Base Drilling and Machining Center's potential is the culmination of collective effort—a synergy of dedication and expertise from our entire team. From the visionary architects steering its development to the skilled operators orchestrating its daily functions, each individual's contribution has been instrumental in reaching this remarkable milestone.

innovators

Innovation is a journey that transcends milestones, demanding collective engagement from every facet of an organization. As we navigate the evolving contours of the NV fuse market, our commitment to excellence remains steadfast. ETI's unwavering resolve to uphold quality, drive innovation, and foster progress solidifies our standing as a frontrunner in the ceramics industry—a legacy we continue to build upon.